Technology and trucking have long been closely associated. Technological advances have changed everything, from the size and shape of trucks to the drivetrain components that propel them and the information available to the owner.

Unfortunately, the newest innovations sometimes don’t provide promised benefits, and some don’t work across multiple segments of trucking.

It goes without saying that the purchase of a tractor is one of, if not the largest, single equipment purchase a carrier will make, with new tractors costing around $110,000 and sleepers averaging $195,000. The cost can go a lot higher if the carrier chooses to augment standard equipment with enhancements such as a larger motor and safety features.

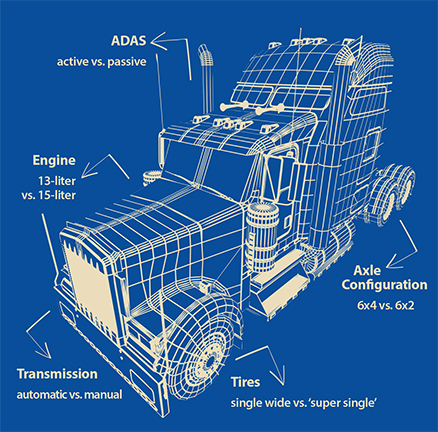

Engine

For instance, 13-liter diesel engines have been around for a long time, but in the last decade, improvements in design, materials, and lubricants have brought them to greater popularity. They provide increased fuel economy over the 15-liter engines they replace, due to both reduced displacement and their lighter weight, and have become standard on tractor models.

Some carriers, however, prefer the 15-liter version for its higher power and proven reliability over time. That’s true of Triple Eight Transport, according to Pardeep Arora, director at the company in Abbotsford, British Columbia, Canada. The carrier operates some 175 Freightliner and International trucks in Canada and the U.S., hauling refrigerated and dry van freight.

“We order only 15-liter engines, due to the mountainous terrain we travel through and the weight of our loads,” said Arora.

Crum Trucking, based in Batesville, Indiana, operates about 175 Kenworth and Volvo tractors, pulling mostly dry van trailers and serving the U.S. and Canada.

Crum has investigated both engines and is also staying with the larger displacement.

“We’ve looked at the 13-liter and at the Cummins X12, but we stayed with the 15-liter,” said Shop Manager Jason Roell. “We decided that for the average speed we travel and the weight we haul, the 15-liter was the best choice.”

Crum has a driver-rewards program that allows drivers who achieve mpg goals to run at higher speeds, up to 75 mph where legal and safe.

Wellington Group of Companies, headquartered in Puslinch, Ontario, Canada, operates Wellington Motor Freight, Wellington Supply Chain, Trucking Proz, and Wellington Holdings. Between these subsidiaries, the company runs approximately 80 Freightliner, Mack, and Volvo trucks in Canada and the U.S., pulling mostly refrigerated and dry van trailers.

Wellington is taking a different approach to engine displacement.

“We’re buying some 13-liter engines set at 455 horsepower for the weight savings and fuel economy,” explained Wellington President Derek Koza.

“Sometimes there is no replacement for displacement,” said Detroit Product Marketing Manager Leonard Copeland. Detroit manufactures DD13 and DD15 engines for Freightliner.

Transmission

Automated manual transmissions (AMTs) have gained wider acceptance at the three carriers and in the industry. “Manual transmissions now account for less than 10% of our heavy on-highway trucks,” said Copeland.

“Automatics are more fuel efficient and require less maintenance,” added Arora.

“We’re 100% AMT, a decision based more or less on fuel economy,” said Koza. “I still think that a professional truck driver can beat an AMT on fuel mileage, but when you average driver behaviors, it’s a better fleet decision.”

According to Roell, Crum recently ordered its first trucks with AMTs. “We plan to go to AMT for all non-training drivers,” he said. “Our reasons are fuel economy and driver availability. A bigger percentage of school graduates have never driven with a manual transmission.”

Crum plans to stay with manual transmissions for trainer trucks in order to provide new recruits with some exposure to shifting before allowing them to drive solo.

Axle Configuration

Another drivetrain innovation — one that hasn’t gained the acceptance of AMTs — is the 6×2 axle configuration. With this setup, only one rear axle pushes the truck; the other is for weight capacity only and may even be ordered as a lift axle. The weight savings helps increase cargo capacity and reduce fuel consumption

Executives at Triple Eight, Crum, and Wellington said they have stayed with the 6×4 configuration for better traction and durability.

Advanced Driver Assistance Systems

One area of innovation that has gained wide acceptance is Advanced Driver Assistance Systems (ADAS). Features such as automatic braking (collision avoidance), lane departure and lane centering, blind-spot information, and more now come standard on many truck models. “Roughly 90% of our Freightliner Cascadias [have] collision-mitigation options,” noted Copeland.

The biggest option for carriers is whether the ADAS is active or passive.

Roell said that Crum prefers the passive systems.

“We use them, but we have them set up to alert the driver and not take control,” he said. “For example, there’s no defueling or braking; the driver keeps responsibility for control of the truck.”

Wellington and Triple Eight prefer the active ADAS. Koza acknowledges the learning curve for drivers. “We get them all, and it drives some drivers nuts,” he said. “We’re trying to change those habits that are causing the ADAS to activate.”

Tires

Single wide or “super single” tires are an option some carriers find attractive for weight savings. None of the three carriers interviewed, however, have changed from the traditional tandem tire configuration. Roell said that Crum experimented with them but couldn’t see a benefit. “The drivers didn’t like the reduced traction, and we really don’t need the weight savings,” he added. He also cited the ability to travel short distances to a repair facility that tandems provide. “With single-wide tires, you’re dead in the water,” he said.

Koza added that some Canadian jurisdictions have not increased per-tire weight limits for single tires and that on-road inventories aren’t “quite there yet.”

One only needs to follow industry news to see the technology that’s on the horizon. Alternative-fuel options, with the most promising being electric, are already being utilized for some applications. As range and dependability increase and cost comes down, increased use is inevitable. For now, diesel still reigns.

And, of course, automated trucks aren’t far away. Current uses are mostly experimental in nature, but self-driving trucks are another inevitability. But that’s a topic for another issue.

Cliff Abbott is an experienced commercial vehicle driver and owner-operator who still holds a CDL in his home state of Alabama. In nearly 40 years in trucking, he’s been an instructor and trainer and has managed safety and recruiting operations for several carriers. Having never lost his love of the road, Cliff has written a book and hundreds of songs and has been writing for The Trucker for more than a decade.