AVON, Ohio — Ready or not, Brake Safety Week is set for Aug. 24-30, 2025. Is your truck ready? If not, there’s still time to prepare.

During this annual weeklong inspection and enforcement event, run by the Commercial Vehicle Safety Alliance (CVSA), commercial vehicles across the U.S., Canada and Mexico are closely inspected to ensure brakes are in good working order.

Brake Safety Week is part of CVSA’s Operation Airbrake initiative, an outreach and enforcement campaign that aims to reduce the number of highway crashes caused by faulty brake systems on commercial motor vehicles. During Brake Safety Week, local, state, provincial, territorial and federal motor carrier safety officials throughout North America will be busy inspecting large trucks and buses, focusing on brake system violations.

The team at Bendix Commercial Vehicle Systems LLC (Bendix) offers practical tips for being prepared, staying safe and passing inspection.

“During last year’s CVSA Brake Safety Week, nearly 13% of the 16,725 vehicles inspected — a total of 2,149 — were placed out of service for brake-related issues,” said Brian Screeton, manager-technical training and service at Bendix.

Many of these violations could have been prevented with proper maintenance and regular equipment inspections, he noted.

“What goes on in the wheel-ends and braking system directly impacts multiple aspects of safe vehicle operation,” Screeton said. “There’s no overstating the importance of keeping up with maintenance and inspection of those areas.

“And remember: How well the brakes and wheel-ends perform when they’re needed is tied to proper operation of many other vehicle systems, including stopping power and helping support the performance of higher-level technologies like collision mitigation,” he continued.

What to expect

CVSA-certified inspectors will conduct routine commercial motor vehicle inspections throughout the week, focusing on brake systems and components. They’ll be checking for:

- Air leaks around brake components and lines;

- Air pressure in the target range of 90-100 psi when checking for air leaks;

- Broken springs in the spring brake housing section of the parking brake;

- Holes in tubing caused by rubbing;

- Mismatched air brake chamber sizes across axles;

- Missing, nonfunctioning, loose, or cracked parts;

- Proper operation of the tractor protection system;

- Proper brake chamber pushrod travel;

- Drum brake S-cam has “cammed over”;

- Slack adjusters on the same axle are not at the same length; and

- Warning device functionality (such as antilock braking system MIL – Malfunction Indicator Light).

During this year’s Brake Safety Week, inspectors will keep a special eye on drums and rotors.

How to be prepared

“Inspections — pre-, post-trip, and regular — can make an important difference toward catching brake-related issues before they become problems, everything from damaged components like air brake chambers or pushrods to loose hoses,” Screeton said.

He and the experts at Bendix recommend checking components on a regular schedule throughout the year.

Every day:

- Check for damaged or loose-hanging air brake chambers, pushrods or slack adjusters.

- Make sure slack adjusters on each axle are extended out to the same angle. Different angles can indicate an out-of-adjustment brake, a broken spring brake power spring or a broken service brake return spring.

- Examine tubing and hose condition, positioning and connections.

Every week:

- Perform a 90- to 100-psi brake application with the wheels chocked and the parking brakes released, and listen for leaks.

- Check air disc brake (ADB) rotors for cracks.

- Inspect drum brake linings for wear and cracks.

Every month:

- Check for moisture in the air system to prevent contamination that leads to component deterioration and system leaks.

Any time you’ve got a vehicle in the shop, it’s also worth greasing the drum brake S-cam tubes and automatic slack adjusters. This quick process helps prevent rust and corrosion, purges out water and contaminants from the components, and also helps keep the slack functioning properly.

Differences between drums and discs

Air disc brakes and drum brakes have a few differing maintenance needs where Brake Safety Week is concerned – key among them the measurement of brake stroke. Because air disc brakes include an internal adjustment mechanism, their brake stroke is not measured externally, as is the case with drum brakes. The internal adjustment mechanism significantly lowers the risk of out-of-adjustment violations.

“Measuring a drum brake’s chamber stroke is a matter of checking the distance from the face of the air brake chamber to the clevis pin with the brakes released, and then again after a fully charged brake application,” Screeton explained. “The difference between these measurements is the brake stroke, and its maximum length depends upon the brake chamber type and size.”

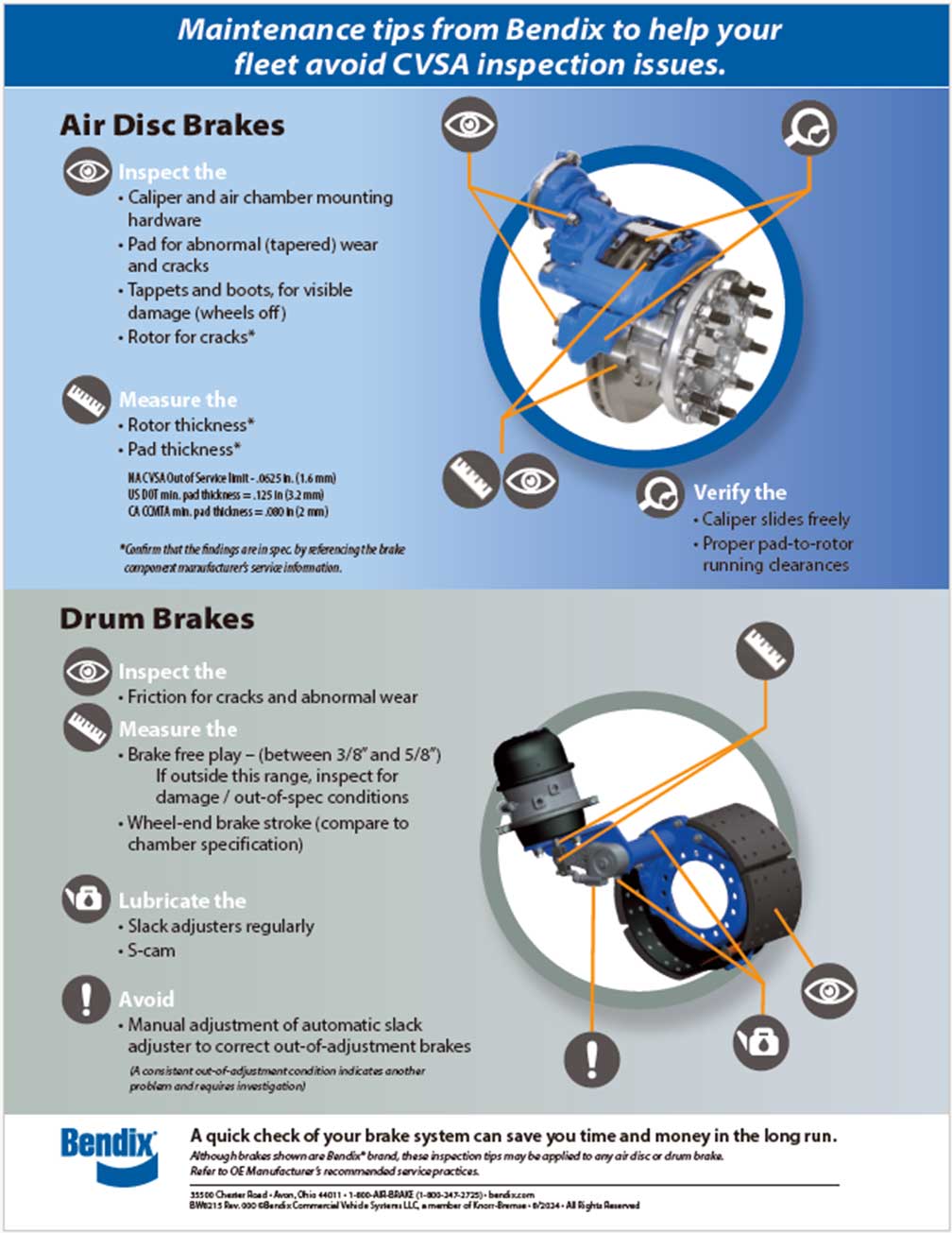

Improperly adjusted brakes can also drag, which impacts fuel efficiency and speeds up pad wear, or result in decreased stopping power. Check out Bendix’s helpful infographic below to note the differing maintenance needs of air disc and drum brakes.

Linda Garner-Bunch has been with The Trucker since 2020, picking up the reins as managing editor in 2022. Linda has nearly 40 years of experience in the publishing industry, covering topics from the trucking and automotive industry to employment, real estate, home decor, crafts, cooking, weddings, high school sports — you name it, she’s written about it. She is also an experienced photographer, designer and copy editor who has a heartfelt love for the trucking industry, from the driver’s seat to the C-suite.