When COVID-19 rose to the forefront of the nation’s news early this year, the trucking industry found itself in high demand. Carriers, company drivers and owner-operators alike worked around the clock to deliver essential goods to all corners of the country. Consumers grabbed most of those goods before another delivery arrived.

While the COVID-19 crisis put most available drivers and trucks on the road, at least for a while, the same didn’t hold true for operations at America’s largest truck-manufacturing plants. Demand for new Class 8 equipment had been trending downward since late 2018, and the pandemic erased industry executives’ hopes that the new decade would spur an increase in truck orders.

However, the trucking industry employs some of the brightest engineers and technicians in the country. Likewise, they have the latest technologies at their disposal. It didn’t take long for several of top truck manufacturers to rethink their strategies and start working to help fight COVID-19.

Over the past few months, numerous truck manufacturers have shifted priorities. International Truck, Volvo North America, Mack Trucks, Navistar and PACCAR Inc. took steps to retool and focus on battling the coronavirus. The companies worked to minimize layoffs, provided personal protective equipment (PPE) for truck drivers in need, and produced personal protective equipment for those high-risk workers outside the trucking industry.

The ability of the nation’s major truck manufacturers to change gears on almost a moment’s notice is a testament to American ingenuity, company pride and corporate responsibility.

First-quarter indicators

PACCAR, parent to Kenworth Truck Co., Peterbilt Motors and DAF trucks, was the first major truck manufacturer to report first-quarter earnings. The impact of COVID-19 on revenue and profits was clear.

While PACCAR’s companies claimed 38% of new Class 8 truck orders in March, inventories began to grow after the delivery of trucks ordered in 2019, suggesting a downturn in the market for new trucking equipment. On the other hand, PACCAR set a record for parts sales in the first quarter of 2020, an achievement likely caused by heavy use of older trucks in the early stages of the pandemic.

Preston Feight, CEO of PACCAR, said the company’s primary concern is employee health.

“Once we take care of that, we’ll ramp back up our production,” he said.

PACCAR suspended operations at plants worldwide in late March, and three major U.S. facilities still remain closed. As these plants gradually reopen, PACCAR plans to take special precautions. All workers will be screened before entering PACCAR facilities and will be provided with personal protective equipment. PACCAR is also working to ensure its workplaces will allow for proper social distancing.

Putting drivers first

It is vital to deliver essential items such as food, paper products and health care supplies during any crisis. Still, carriers realize that unhealthy drivers will only delay deliveries.

The first task for International Truck was to equip drivers with personal protective equipment to shield themselves from exposure to the virus. If exposed, the company hoped drivers would be healthy enough to self-quarantine and fight off COVID-19’s potentially deadly effects. International Truck joined forces with business partners Triumph Business Capital and TriumphPay to purchase and distribute $75,000 worth of personal protective equipment to International dealerships in the U.S. and Canada.

The three companies realized the need for protecting drivers after hearing from truckers like Ingrid Brown, an owner-operator and company driver in Illinois.

Brown has been a driver for more than 40 years. Throughout her career, she has been an advocate for the needs of drivers.

“While large fleets have a solid distribution network to provide protection to their drivers, many drivers for smaller fleets and independent drivers, like myself, are on our own,” she said.

Brown said that personal protective equipment, ranging from hand sanitizer to disinfectant wipes and masks, is hard to come by. International is doing an excellent service to drivers by helping them access essential safety items, she added.

International Trucks also launched “International Cares,” a program that allows buyers to delay payments for six months on new purchases and offers free access to “International 360,” a tool to help carriers safely manage fleets. International has also provided its worry-free truck-maintenance program at no charge for up to nine months or 100,000 miles. In April, before launching “International Cares,” company service centers provided 10,000 meals to drivers who were working long hours to deliver COVID-19 relief supplies.

Michael Cancelliere, president, Truck, Navistar, said his company’s efforts are just a few of many initiatives to help drivers whether the country is in crisis or not.

“[PPE is] still sparse at stores,” he said. “This is just another way we can show that International cares, and we’re with you for the long haul.”

Retooling to defeat an invisible enemy

Companies such as the Volvo Group and its subsidiary, Mack Trucks, are using the slowdown in truck manufacturing to design, test and produce personal protective equipment to help medical facilities and workers in other high-risk occupations.

“Our employees and communities are extremely important to Volvo Trucks,” said Peter Voorhoeve, president of Volvo Trucks North America. “We want to do what we can to help during the current situation.”

Volvo has taken steps using engineers and assembly-line employees to design and manufacture personal protective equipment. The company has also provided financial and in-kind donations to nonprofits that are battling the crisis.

Volvo’s facilities in Greensboro, North Carolina; Dublin, Virginia; and Hagerstown, Maryland, have taken the lead in the company’s efforts to use its ingenuity and technology to meet new challenges posed by COVID-19.

In one plant, employees from various departments teamed to design prototype face shields in cooperation with medical professionals. The face shield, team leaders said, is one of the most challenging pieces of equipment to find in the area. With the help of 3-D printers, Volvo is now producing face shield headbands and ear guards. Employees working from home have access to 3-D printers and provide them for delivery to area hospitals and nursing homes. Likewise, Volvo is donating healthy snacks to childcare providers.

“The ingenuity of employees at the Hagerstown facility has never been more evident than during COVID-19,” said the facility’s vice president of powertrain production, Marcus Minkkinen. Using the same 3-D printing technology, employees at other Volvo locations are also manufacturing personal protective equipment. In addition, Volvo recently donated $68,000 to nonprofits serving the area of its North Carolina facility.

“It’s great to see the drive and commitment from our employees at several Volvo facilities,” Voorhoeve said.

Like Volvo Trucks North America, Mack Trucks has been manufacturing personal protective equipment at its Lehigh Valley Operation (LVO) plant in Pennsylvania.

“The Mack Team is committed to doing what we can to help the communities in which we live and work,” said Rickard Lundberg, vice president and general manager at LVO. He noted that producing PPE is just another example of the company rising to the challenges of fulfilling vital needs — problems it has accepted for over 120 years.

Going beyond delivering freight

The steps major truck manufacturers have taken in recent months may have taken their employees out of their comfort zones. Still, the trucking industry employs some of the brightest and most qualified professionals in the country, and they regularly adapt to changing government regulations for equipment and shifting market forces. Using the best of the best allows truck manufacturers to rise up and become a driving force when many carriers are sidelined. Independent truckers like Ingrid Brown not only inspire manufacturers to reach new heights but also support their efforts.

With personal protective equipment hard to come by, Brown said knowing that truck manufacturers are assisting in taking care of drivers offers comfort.

“I can protect myself, assist in slowing the spread of this virus and still do my job,” she said.

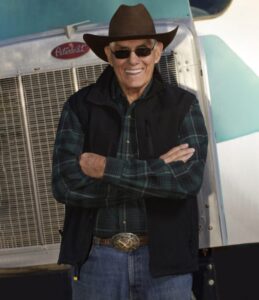

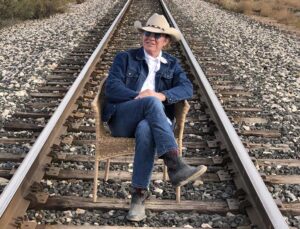

Since retiring from a career as an outdoor recreation professional from the State of Arkansas, Kris Rutherford has worked as a freelance writer and, with his wife, owns and publishes a small Northeast Texas newspaper, The Roxton Progress. Kris has worked as a ghostwriter and editor and has authored seven books of his own. He became interested in the trucking industry as a child in the 1970s when his family traveled the interstates twice a year between their home in Maine and their native Texas. He has been a classic country music enthusiast since the age of nine when he developed a special interest in trucking songs.

Truck OEMs retool to keep employees on the job, fight COVID-19 pandemic

Comment