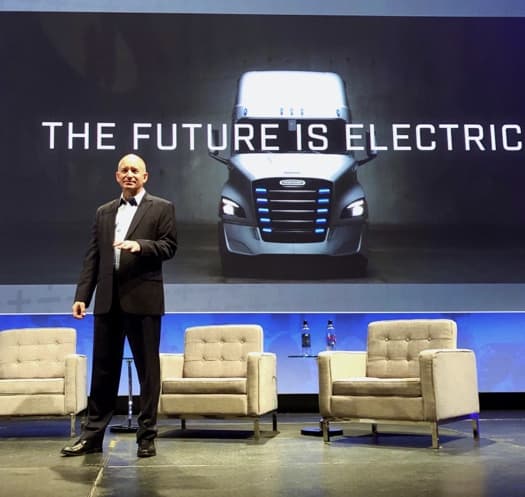

LONG BEACH, Calif. — Roger Nielsen, president and CEO of Daimler Trucks North America (DTNA), Wednesday declared battery-electric vehicles as the solution to achieve emissions-free commercial transportation in North America.

Speaking to a crowd assembled in Long Beach at the ACT Expo, Nielsen said, “The road to emissions-free transportation is going to be driven with battery-electric vehicles. I believe the future is electric.”

The road to emissions-free driving, he said, does not include plug-in hybrids for DTNA. Near-zero-emissions natural gas medium- and heavy-duty vehicles are currently available and will continue from Freightliner as an interim solution until full commercialization of the battery-electric Freightliner eM2 and eCascadia.

The company sees potential for hydrogen fuel cells to extend battery-electric truck range, but does not see it as viable in the near term.

The vision of electric vehicles does not exclude fuel cells: “I can see glimpse of it over the horizon, but it will not be this generation of engineers who will be delivering it,” continued Nielsen.

To hasten the arrival of zero-emission commercial transport, three goals must first be achieved, Nielsen said.

First, the industry must work together to establish a common battery-electric vehicle charging infrastructure. Daimler AG is a founding member of CharIN, an organization whose aim is to standardize charging requirements for electric vehicles, including commercial vehicles.

Second, batteries must become cheaper, lighter and more powerful. DTNA is leveraging its global network to develop proprietary batteries for its commercial vehicles that meet the standards of quality, durability and integration that customers demand.

Finally, the real cost of ownership for customers must be strengthened through increased incentives, decreased maintenance costs, and cheaper energy costs. Organizations such as the South Coast Air Quality Management District (SCAQMD) will be instrumental in creating a viable business case for electric trucks. A $16 million grant from SCAQMD partially funds the Freightliner Electric Innovation Fleet.

The key to ensuring electric vehicles are ready for commercialization is testing, Nielsen said. DTNA and its global affiliates exhaustively test their electric vehicles over millions of miles on the track and in the real-world. With its first electric truck already in customer hands, DTNA plans to put nearly 50 on the road by the end of the year. This includes a test fleet and the Freightliner Electric Innovation Fleet shared between Penske and NFI. Affiliated brands Fuso and Mercedes-Benz trucks have already begun deliveries of the battery-electric eCanter and eActros in Asia, Europe, and North America. By the end of 2019, nearly 200 battery-electric vehicles powered by Daimler will be deployed for testing, co-creation and collaboration worldwide.

“For our engineers, these early customer partners are our test drivers. We want them to test these vehicles to their extremes. We want to see the failures so we can engineer solutions,” Nielsen said.

To enable rapid scale-up of thoroughly tested and validated electric vehicles, DTNA said Wednesday that it will begin converting the Portland manufacturing plant to produce electric Freightliners. The plant lies just blocks from DTNA’s LEED Platinum headquarters. The plant renovations begin next year with series production scheduled to begin in 2021.

The company’s decision to bring electric vehicle production to Portland was based multiple factors, including Portland’s proximity to the huge demand for electric vehicles in California, Nielsen said. In addition to production, the Portland manufacturing facility will also host a battery storage facility and an electric vehicle co-creation center, where the e-consulting team will collaborate with customers. Here they will integrate electric trucks into their fleets from order intake through the second life of the truck.

Last year DTNA formed the Freightliner Electric Vehicle Council composed of 30 customers with strong use-cases for electric trucks to further drive its sustainable transportation program. The company is working with the council members to ensure a holistic approach to launching electric trucks. Members of the customer council benefit from co-development of deployment strategies for battery electric vehicles including applicable use cases, current legislation and requirements for facilities, charging infrastructure, and service support.

The Freightliner eM2 truck is an electrified solution for local distribution, pickup and delivery, food and beverage delivery, and last-mile logistics applications. The Freightliner eCascadia is a Class 8 tractor designed for local and regional distribution and drayage. Both trucks enter series production in 2021. The Freightliner eCascadia and eM2 are part of Daimler Trucks’ global electrified truck initiative, joining the company’s Thomas Built Buses all-electric Saf-T-Liner eC2 school bus, the FUSO eCanter, and the Mercedes-Benz eActros.

The Trucker News Staff produces engaging content for not only TheTrucker.com, but also The Trucker Newspaper, which has been serving the trucking industry for more than 30 years. With a focus on drivers, the Trucker News Staff aims to provide relevant, objective content pertaining to the trucking segment of the transportation industry. The Trucker News Staff is based in Little Rock, Arkansas.