One thing that large trucks and small automobiles have in common — at least since 1994 — is that each one sold in the U.S. is required to have self-adjusting brakes.

The comparison ends quickly, however. Drivers of automobiles aren’t required to inspect the adjustment of their brakes before driving. They are under no obligation to check brake lines to make sure they’re secured and that no “chafing” is occurring. There’s no form to complete, attesting that the brake fluid level was checked and is satisfactory. For the most part, they hop into their four-wheelers and drive.

On the other hand, drivers of commercial motor vehicles (CMVs) deal with all these things. There’s even a special week set aside during which law enforcement concentrates on brake safety, performing inspections nationwide to identify brake issues on CMVs.

This year, the Commercial Vehicle Safety Alliance (CVSA) will be conducting its annual Brake Safety Week August 21-27. The special focus this year will be brake hose chafing, although inspections will also include brake components and adjustment.

CVSA is a partnership between government agencies, law enforcement and trucking industry businesses. The CVSA determines inspection parameters, including what constitutes a minor violation versus one serious enough to put the vehicle out of service (OOS). The organization develops inspection techniques and provides guidance to law enforcement personnel so they know what, and how, to inspect.

Many company drivers have an attitude that the truck owner (the carrier) is responsible for keeping the equipment in peak operating condition. Drivers who own their trucks know what their responsibilities are — but inspection of brake components is time-consuming and often dirty work, crawling underneath the vehicle to inspect components that can’t be seen from above.

It’s easy for a driver to become complacent about brake issues, assuming they’ll be checked out and repaired during the truck’s next maintenance visit. However, because of the potential for catastrophic damage if brakes on a CMV aren’t working at full capacity, it’s important the driver be fully confident the entire braking system is in good shape.

During Brake Safety Week 2021, a total of 35,764 CMVs were inspected in 50 North American jurisdictions (some states and) provinces did not participate). Of the total inspections, 12% were placed OOS for brake-related violations. Other violations resulted in warnings or citations but weren’t serious enough to warrant an OOS order.

Keep in mind that inspection results data reflects only the percentage of trucks that are actually stopped and checked. Some media outlets regularly (and incorrectly) assign those number to all of the CMVs on the road.

Trucks are chosen for inspection for different reasons, ranging from totally random selection to deliberate selection of trucks with visible issues, older trucks or even trucks from a particular industry, like logging or trash hauling. Some inspectors deliberately select trucks that appear more likely to have violations. That’s good for highway safety, but can reinforce public perception that trucks are dangerous.

To ensure a positive experience during an inspection and to maximize the vehicle’s safety, the driver needs to know the condition of the entire braking system, including its individual parts.

Because of vehicle movement, reinforced rubber or thermoplastic hoses are used where the lines are expected to move around. Supports and brackets are often used to keep them separated so they cause damage, known as chafing. These supports and brackets can break or move. In addition, lines used to replace old or damaged lines may not be of the same length as the original, allowing for more movement or contact with other hoses or parts of the vehicle.

Identifying chafing isn’t difficult, but frequent inspections should be made. This may require a flashlight to see lines in shadowy areas or at night. Lines that contact an object, including other lines, should be moved or adjusted to prevent contact. Lines should be replaced when chafing become obvious.

Air leaks are another issue that is easy to overlook, especially on trailers. Service brake lines are charged with compressed air when the brake pedal is depressed or a hand brake, if equipped, is pulled. Unfortunately, an air leak in a service line toward the rear of a trailer can be difficult to hear from the cab of the truck. To compensate for this, try opening the cab windows while depressing the brake pedal and listening for leaks. It’s even better if two people work together, one depressing the brake while the other listens.

Brake hoses that are kinked or that have improper repairs are also cause for concern. Occasionally an emergency brake line repair might consist of a splice made with a piece of metal pipe and a couple of heater-hose clamps. While such a repair might be enough to get the brakes working and get the truck out of the road, they can be dangerous and are cause for being placed OOS during an inspection.

Beneath the truck, slack adjusters should be checked for proper travel when brakes are applied. Travel distances can differ based on the size and the manufacturer of the parts, so the driver may need to research to determine the correct travel measurement to look for. The National Transportation Safety Board (NTSB) and most manufacturers recommend that adjusters that fail NOT be adjusted to bring them into compliance. If they are out of adjustment, they should be replaced.

The thickness of brake shoes or pads is another item that can result in an OOS order. Generally, brake shoes must have a quarter-inch remaining. Pads for disc brakes can be an eighth of an inch. On many trucks, the pads are exposed and easily visible. On others, there may be an inspection plate that must be removed to observe thickness.

Check drums and rotors for cracks, too. Small “check” cracks in the drum surface that contacts brake shoes are normal, while any cracks elsewhere can be grounds for being place out of service.

Knowing the condition of the braking system can help ensure drivers are getting maximum stopping power and help them keep rolling in the event of an inspection.

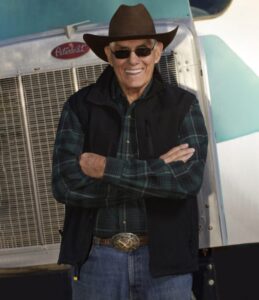

Cliff Abbott is an experienced commercial vehicle driver and owner-operator who still holds a CDL in his home state of Alabama. In nearly 40 years in trucking, he’s been an instructor and trainer and has managed safety and recruiting operations for several carriers. Having never lost his love of the road, Cliff has written a book and hundreds of songs and has been writing for The Trucker for more than a decade.