When a month starts off, as September did, with one of the most damaging hurricanes in U.S. history, both freight levels and fuel prices are impacted. When hurricane Ida made landfall as a Category 4 hurricane near Port Fourchon, Louisiana, Aug. 29, its eye narrowly missed New Orleans as it destroyed thousands of homes and left huge areas of the state without power.

But Ida wasn’t finished.

The storm lingered, dumping massive amounts of rain as it crept from the Gulf Coast to the Northeastern U.S. before finally drifting off into the Atlantic Ocean Sept. 2. Ida spawned flash floods and tornadoes that caused at least 95 deaths — and billions of dollars in destruction.

Shipping was disrupted along the entire path of the storm, and nine refineries reduced production or shut down. According to the U.S. Energy Information Administration (EIA), refinery production was reduced by an average of 713,000 barrels per day for the entire month.

Over the next two months the national average diesel fuel price rose more than 40 cents per gallon.

Through it all, demand for truck capacity remained strong as both freight volumes and revenues increased, according to the ACT Research For-Hire Trucking Index. Using polling data received from trucking service providers, ACT compiles the index using 50 as an indicator of flat activity — above 50 means volumes are expanding, while lower means they’re contracting.

Freight volumes have been expanding for 16 consecutive months, according to the index. The rate, however, is slowing.

“Although it increased in September, the volume index is still considerably below the 65.5 average of the past 12 months,” said Tim Denoyer, ACT vice president and senior analyst, in an October 21 release.

Denoyer blamed supply bottlenecks for a result that could have been even better.

“In particular, chip and part shortages are hindering vehicle production,” he claimed.

That’s a situation that hits the industry in multiple ways. If the industry could get its hands on more trucks, more freight could be moved. And vehicles, including parts and components needed to build them, make up a large portion of freight moved.

Denoyer also mentioned that vaccine mandates (or the threat of them) may be exacerbating the driver shortage by discouraging qualified drivers who are against the mandate from applying.

The American Trucking Associations (ATA) reported a 2.4% increase in its Truck Tonnage Index following a smaller gain of 0.3% in August.

“September’s sequential gain was the largest in 2021,” said Bob Costello, ATA chief economist. “It is good that tonnage rose in September, but it is important to note that this is happening because each truck is hauling more, not from an increase in the amount of equipment operated as contract carriers in the for-hire truckload market continue to shrink from the lack of new trucks and drivers.”

Compared with September 2020, the ATA index rose 1.7%, representing the first year-over-year increase since May. For the year to date, tonnage is unchanged. That’s interesting, because 2020 saw a huge decrease in freight levels in March, April and May due to COVID-19 shutdowns before recovering later in the year. For 2021, there hasn’t been such a decline and rebound. No matter, at the end of nine months of 2021 freight levels are right where they were a year ago.

It’s important to point out that the ATA index represents mostly contract freight.

Interestingly, the backup of ships waiting to unload at West Coast ports may be contributing to the shipment numbers. Chassis, both rail and truck, are hard to come by. One reason is the difficulty in getting steel to build them. India, the world’s second-largest steel producer, still hasn’t resumed full production after diverting oxygen supplies to hospitals for COVID-19 patients. China, penalized for dumping steel on world markets, added the 200% penalty to their prices.

The truck chassis that are available are often stuck at trucking carriers’ parking lots, waiting for the port to accept the return when space is available. With cargo containers stacked everywhere, the ports required carriers to make appointments to return chassis, sometimes making them wait a week or more.

All the port issues have resulted the use of alternate methods for moving freight. For example, the lack of a rail chassis for a container might result in that container being taken to a local warehouse instead of making a 1,500-mile rail trip from the port to a railyard near its destination. The cargo would be unloaded from the container and then loaded into a standard dry van or refrigerated trailer for its journey to the receiver.

This practice does several things to shipping data. First, it adds to the amount of freight trucking is hauling. Capacity is reduced, since that trailer is removed from the pool of trailers to haul loads, driving spot freight rates higher.

According to Truckstop.com, the week ending Oct. 1 showed spot load postings were still increasing. The organization credited supply chain disruptions for keeping volume stronger than expected for the season.

Truckstop.com reported load postings were much higher than normal, with four days of the week over one million loads posted as compared to a normal load volume of 400,000 per day. Rates for the week stayed even at an average of $2.95 per mile. It marked the 55th consecutive week that average rates topped $2.40 per mile. The five-year average for rates on the website is $2.10 per mile.

The Bloomberg/Truckstop.com survey for the third quarter, released Nov. 3, showed more than half of surveyed drivers (55%) expect spot rates to rise further in the next six months.

Many (67%) respondents said they expect the freight market to remain tight for the rest of the year, while 74% indicated they expect spot rates will remain steady or even rise in 2022.

For the trucking industry, equipment may be hard to come by, but enough freight is available to keep trucks full and rates high for the foreseeable future.

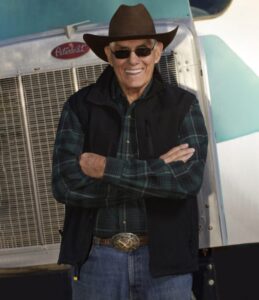

Cliff Abbott is an experienced commercial vehicle driver and owner-operator who still holds a CDL in his home state of Alabama. In nearly 40 years in trucking, he’s been an instructor and trainer and has managed safety and recruiting operations for several carriers. Having never lost his love of the road, Cliff has written a book and hundreds of songs and has been writing for The Trucker for more than a decade.