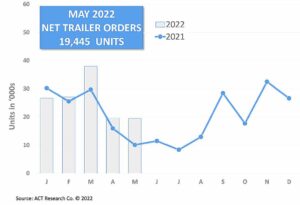

COLUMBUS, Ind. – May net US trailer orders of 19,445 units were virtually unchanged compared to April, down just 0.8% month-over-month, but were 93% higher compared to May of 2021, according to this month’s issue of ACT Research’s State of the Industry: U.S. Trailer Report.

ACT Research’s State of the Industry: U.S. Trailers report provides a monthly review of the current US trailer market statistics, as well as trailer OEM build plans and market indicators divided by all major trailer types, including backlogs, build, inventory, new orders, cancellations, net orders and factory shipments.

It is accompanied by a database that gives historical information from 1996 to the present, as well as a ready-to-use graph packet, to allow organizations in the trailer production supply chain, and those following the investment value of trailers, trailer OEMs, and suppliers to better understand the market.

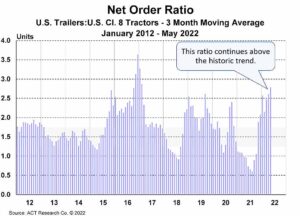

“Order placement remained choppy in May, with dry vans, up 32% m/m, and bulk tank, 42% m/m higher, responsible for the total industry uptick,” Jennifer McNealy, director–commercial vehicle research & publications at ACT Research, said. “OEMs continue to negotiate with fleets, and that effort is building a large group of staged/planned orders that are not yet officially posted to the backlog. Once OEMs gain sufficient confidence in their availability to open 2023 production slots, expect a surge of orders to be ‘officially’ accepted.”

McNealy said the industry has normally not been willing to push commitments past 12 months, nor open a new calendar year this early in the preceding year, but recent years, including the pandemic-battered 2020/21, have been anything but normal.

“We expect some OEMs to begin considering longer order boards, with appropriate cost/price protections,” McNealy said. “The order board slid sequentially again in May; the second month-over-month decline in backlog since last October. Dry vans, platforms, and low beds all shared responsibility for the slide, with the backlog for tanks, both liquid and bulk, growing. Expect backlog to contract as we move through early summer, and for this trend to reverse when 2023 order boards are fully opened.”

The Trucker News Staff produces engaging content for not only TheTrucker.com, but also The Trucker Newspaper, which has been serving the trucking industry for more than 30 years. With a focus on drivers, the Trucker News Staff aims to provide relevant, objective content pertaining to the trucking segment of the transportation industry. The Trucker News Staff is based in Little Rock, Arkansas.