WASHINGTON — Adoption of the newest, cleanest diesel truck technology has jumped by 6 percent in one year and now makes up more than one-third of all trucks on the road, with some states having new technology diesel in more than two-thirds of their fleets, says new research from the Diesel Technology Forum (DTF).

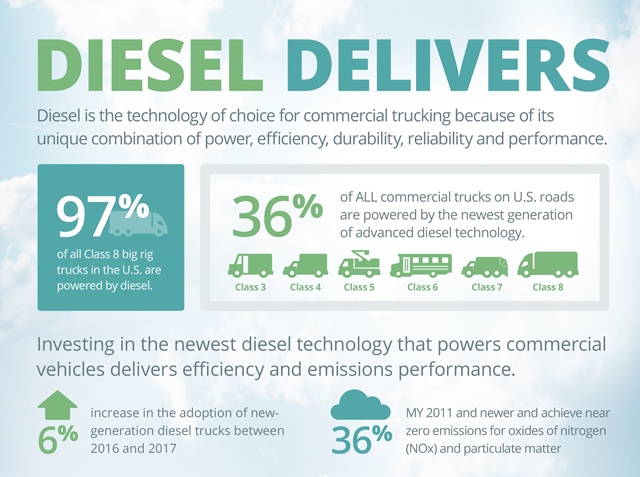

According to analysis by DTF of 2017 U.S. vehicles in operation data (Classes 3 through 8) provided by IHS Markit, 36 percent of all commercial diesel trucks on U.S. roads – from the ubiquitous white box delivery trucks on up to the largest 18 wheelers – are now powered by the newest generation of diesel technologies (MY 2011 and newer), up from just 30 percent in 2016 and 25.7 percent in 2015.

The DTF considers the newest generation of diesel power to be those technologies which incorporate selective catalytic reduction and particulate control technologies, which combine to achieve stringent new EPA emissions requirements for NOx emissions of no more than 0.20 grams per brake horsepower hour (g/BHP-hr.). This is in addition to particulate emissions levels of no more than 0.01 grams per brake horsepower hour (g/HP-hr.) established in 2007. In the case of heavy-duty trucks, such technologies were manufactured beginning in 2011.

“Especially for the largest of trucks, no other fuel matches what the newest generation of diesel technology continues to improve upon: efficient performance, low-emissions, reliability, durability, low-cost operation, and maximum flexibility in utilization, routing and fueling,” said Allen Schaeffer, executive director of the Diesel Technology Forum. “In comparison, about 21 percent of all commercial trucks (Class 3-8) use gasoline and about 4 percent use other fuels, with those using natural gas amounting to less than 1 percent.”

Schaeffer said just a 6 percent increase in the number of new-technology diesel trucks on the road has delivered important benefits in the form of cleaner air, fewer carbon dioxide emissions “The more than 4.9 million new-technology diesel trucks now on the road have removed more than 26 million tonnes of nitrogen oxides (NOx) and 59 million tonnes of carbon dioxide (CO2) from the air,” he said. “On average, truckers saved $2,600 in fuel, which adds up to 138 million barrels of crude oil – that’s 50 percent of the entire U.S. Strategic Petroleum Reserve, saved by just a few thousand trucks.”

The U.S. trucking fleet is transitioning to newer diesel technology, which means immediate fuel savings, lower greenhouse gas emissions and cleaner air, Schaeffer said.

With diesel costs rising and fuel representing 61 percent of total cost of ownership, transportation companies can realize a first-year savings of $26,687 when upgrading from a 2012 sleeper model-year truck to a 2019 model.

This represents a 15.5 percent increase in savings compared with a similar analysis a year ago upgrading to a 2018 model when diesel prices registered $2.57. Based on data analytics from Fleet Advantage’s ATLAAS (Advanced Truck Lifecycle Administrative Analytics Software), these calculations remain a critical part of a fleet’s asset procurement strategy, which includes identifying the TIPPINGPOINT — the point at which a truck reaches economic obsolescence, and costs more to operate than to replace with newer equipment.

The adoption rates of the newest diesel technologies in these states’ diesel fleets varies widely. Indiana (66 percent), Tennessee (60 percent) and the District of Columbia (48 percent) have the highest percentage of new-generation Class 8 diesel trucks.

Meanwhile, between the years 2016-2017, Florida (81 percent), California (37 percent) and New Hampshire (35 percent) have the fastest-growing heavy duty clean diesel fleets.

A full state-by-state breakdown is available on the Forum’s website at https://www.dieselforum.org/in-your-state

“Over the last decade, truck and engine manufacturers and their suppliers have fundamentally transformed diesel technology to near-zero emissions performance while also increasing its fuel efficiency,” Schaeffer said. “Diesel’s continued dominance as the technology of choice for heavy-duty trucking reflects the technology’s proven record of continuous improvement and low-cost operation.”

The Diesel Technology Forum is a non-profit organization dedicated to raising awareness about the importance of diesel engines, fuel and technology. Forum members are leaders in clean diesel technology and represent the three key elements of the modern clean-diesel system: advanced engines, vehicles and equipment, cleaner diesel fuel and emissions-control systems.

For more information, visit http://www.dieselforum.org.

The Trucker News Staff produces engaging content for not only TheTrucker.com, but also The Trucker Newspaper, which has been serving the trucking industry for more than 30 years. With a focus on drivers, the Trucker News Staff aims to provide relevant, objective content pertaining to the trucking segment of the transportation industry. The Trucker News Staff is based in Little Rock, Arkansas.