Supply chain problems didn’t start with the COVID-19 pandemic. They’ve been constantly disrupted over the past two decades, thanks to the advent of online ordering, rapidly developing technology and an aging workforce.

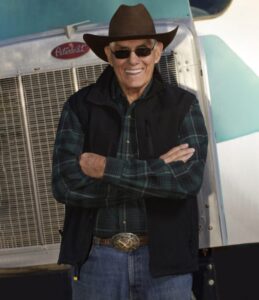

“Supply chain disruptions have become our new normal, and we should expect and plan for them in the foreseeable future,” said Chuck Moyer, former president of the Customized Logistics and Delivery Association.

In other words, supply chain issues are nothing new.

“Pre-pandemic, we’d see issues in one part (of the supply chain),” said Adam Hill, president and chief operating officer for the Scarbrough Group of Companies. “We could always finagle around one issue. If they hit at one time, you’d have chaos.”

Hill pointed out that another of the big weaknesses in the supply chain can be traced back to the recession of the early 2000s. But that’s not the only factor.

“It goes all the way back to FedEx and Amazon,” Moyer said. “They changed consumer expectations. Before that, the delivery companies would tell the consumer when to expect their orders.”

Instead of shippers telling consumers, “Your package will be delivered in three weeks” — as in previous shipping models —shippers started asking consumers, “When would you like it delivered?”

Hill said that shift in the business model completely changed the way people buy things now. Instead of products being ordered and shipped to big-box retailers, the market is seeing more items being shipped directly to consumers.

The previous way of doing things had been stable for decades, he said, and now that stability is gone. That the supply chain now resembles more of a “hub-and-spoke” model, like an airline.

“Previously they were stable,” Hill said of the world’s supply chains. He said that in the past, the freight industry was the information collector. Now it is providing the information, as well as the solutions.

Hill said the lessons spurred by this shift will take time to learn.

However, when COVID-19 hit as a global pandemic 2020, the final stressor on the supply chain crashed into place.

“China was locked down for nine weeks due to the virus. Factories were shut down. Production ceased. That caused the steam ship lines to stop servicing those ports,” Hill said.

“Then, COVID started making its way around the world. Europe shut down. The U.S. shut down,” he continued. “And just as manufacturing in China picked up again, we started to see skyrocketing consumption in the U.S. fueled by lockdowns.”

The world’s adaptation to the pandemic and partial return to “business as normal” has not alleviated supply-chain stressors.

“Fast-forward (to) now, and we’re seeing the ports in LA and Long Beach trying to handle a 30-plus-percent increase in traffic from their pre-pandemic numbers. Those goods are locked up even now as things ease a bit, but it’s still chaos,” Hill noted.

“The warehouses on the coasts are 130% full. We have more than 20 loads for every individual truck that’s available to come out on the West Coast,” he added. “It’s just a perfect storm of problems. In the past, we may have had one of these problems and the rest of the supply chain could figure a way around it. We can’t do that now. That’s why I describe what’s happening as chaos. Not disruption. Chaos.”

The issue has hit U.S. consumers, who had quickly become accustomed to receiving online orders in a matter of days — or, in many cases, overnight — particularly hard.

“During the pandemic, we saw Americans change their purchasing habits with many consumers buying more large and small products online,” said Darrel Harris, president and COO of Yellow Corp., said. “This change has led to tighter freight capacity; however, our freight professionals are hard at work to ensure Americans receive their goods as promised.”

Just a few weeks ago, the expectation was that the supply chain and problems seen in it would ease in 2022.

Then Russia invaded Ukraine. Now Russia, one of the world’s largest oil and natural gas producers and suppliers, is facing economic sanctions and could retaliate by holding back its crude oil and gas supplies from countries that oppose its war on Ukraine.

For now, members of the trucking industry can only watch and wait.

“We are concerned about diesel fuel prices going up and certainly watching for other impacts on the supply chain,” said Norita Taylor, director of public relations for the Owner-Operator Independent Drivers Association.

“We’ll definitely see some impact,” Moyer said. “It’s hard to know the outcome. Hopefully (Russian President Vladimir) Putin and Russia will become more cooperative. It’s hard to predict.”

Moyer said it’s likely that the U.S. will see an increase in fuel prices that will impact all sectors.

“That will drive prices up across the board,” he said. In addition, he noted that cyber-attacks on infrastructure, which the U.S. has seen on a small scale, could become a tool of war.

“I think there’s a higher chance we could see that impact,” Moyer said. “We’ve (already) seen impacts on the electrical grid and pipelines.”

Once invisible to most consumers, the supply chain has entered Americans’ daily vernacular, thanks to media’s coverage recent snags and blockages. Now the supply chain is one of the more familiar aspects of the economy for everyday Americans.

A large part of curbing consumer anxiety and stabilizing the supply chain will depend on how the workforce incorporates technology and use their creativity. One new way of dealing with the supply chain issues is linking all stakeholders and keeping them up to date one their goods.

“Today it’s very fragmented,” Moyer said, adding that in the near future, stakeholders will be sharing information throughout the supply chain from beginning to end and will have access to the same information.

“When I look at the supply chain issues of today, I believe the root cause is that most companies lack visibility and measurements in their supply chain,” Moyer said. “What they need is a ‘control tower’ — a way to gain full visibility, all the way from the manufacturing of the goods through every leg of the supply chain.”

Moyer also said he believes having real-time systems that are linked to all of a company’s stakeholders and can monitor weather and industry issues will play a role in the supply chain.

“This will help everyone in the supply chain to plan accordingly,” he said. “This will allow optimization of every component in the supply chain. If you have that control tower, you can optimize everything from your agreements to your scheduling, insurance, inventory control (and) placement of facilities, and adjust as needed and keep your customers informed. Creating a proactive culture and solution is an investment and provides a distinct advantage and ROI.”

Of course, professional truck drivers are needed to make everything work, and a lack of drivers has led to a number of public-private partnerships working to get more qualified hands on the wheels. Companies are also putting extra effort in to retain current drivers.

“The nation’s driver shortage remains a significant industry wide concern,” Harris said. “As a result, we’re focused on increasing the number of permanent driver academies and enhancing driver recruitment and retention. Yellow Corp. has 16 permanent driver academies, with additional programs being added as needed. In addition, we’ve boosted hiring for other critical jobs, including dock and mechanic positions, which is just as important as hiring drivers.”

Cooperation and a coordinated effort by all parties involved are vital to a healthy supply chain.

“Partnerships matter,” Hill said. “Providers need to do business with people who are like-minded. They must do business with people they trust and know they can depend upon. This is the time where service wins and good partnerships are how you provide a high level of service. The world relies on those of us who make the supply chain work and we need to work together to make that happen.”

Planning ahead and finding a way to anticipate unexpected events are also important links in the chain.

“Disruptions are ongoing and somewhat unpredictable, but planning now and changing the way we do business will position companies to take advantage of those disruptions in the future, and gain market share” Moyer said, adding that, in his view, if things stay stable, improvements will follow.

“Ride (it) out and expect disruptions,” Moyer said. “Disruptions are not new.”

Joseph Price has been a journalist for almost two decades. He began in community media in 2005 and has since worked at media outlets in Virginia and Arkansas. He is also a commercial drone pilot and video editor. He hosts a weekly community radio show focused on goth, metal and industrial music that airs Wednesday evenings at 6 p.m. at www.kuhsradio.org.